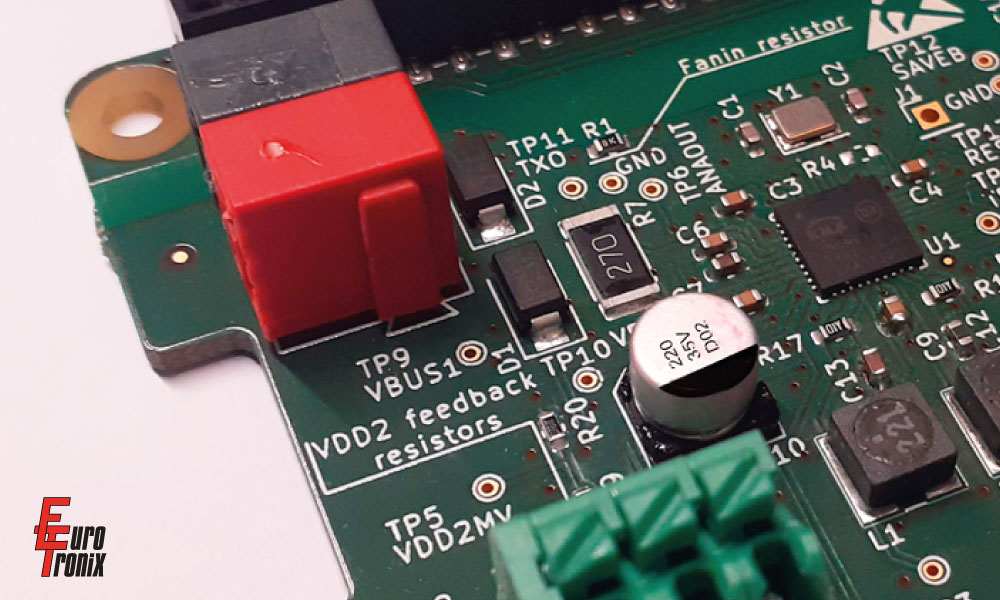

220µF in 8mm height, unique solution in the market by Capxon and Eurotronix

Thanks to the teamwork between Capxon and Eurotronix, the customer's requirements are met by condensing 220µF / 35V in 8mm height

Leading company in domotics sector has been the player in one of the latest success projects of Eurotronix, which required an aluminum electrolytic capacitor, essential in their products to meet the KNX standard. In addition, it needed special mechanical characteristics, with the restrictions imposed by the aesthetic requirements of the market.

Project requirements:

For the customer this capacitor is essential in their KNX system since, in case the Bus voltage drops, it sustains the power supply while the system status is stored in flash memory. For this, it must have a capacity of at least 220µF; and as the Bus operates at 24V (with up to 30V supplies), the capacitor's nominal voltage cannot be less than 35V.

In addition, since the market trend is to make designs with increasingly smaller dimensions, this capacitor had to be no more than 8mm high.

These were the technical parameters required by the customer:

- Capacitance: 220 µF

- Voltage - Rated: 35V

- Lifetime @ Temp: 2000Hrs @ 105º.

- Diameter: 10.00mm

- Height (Max.): 8.20mm (including maximum tolerance)

- Surface mount land size: 10.30mm x 10.30mm

- Mounting Type: Surface Mount (SMD)

The challenge resided in the 8mm height, because standard capacitors with these specifications are available on the market, but are rarely found below 10mm.

Project solution:

Eurotronix's technical team of Field Application Engineers (FAEs) and Product Managers (PMs) found a part number in manufacturer Capxon's DV series that partially matched the requested parameters.

FAEs from both companies scheduled a videoconference to evaluate the customer's requirements and start working on the project. Eurotronix informed Capxon about the height challenge, which was studied and finally the manufacturer developed a specific low-profile capacitor for this project, fitting 220µF / 35V in 7.7mm, something unique and rarely found in the market.

Eurotronix, customized projects thanks to the technical team

Once again, Eurotronix has developed a specific and customized solution for its customers thanks to the PM and FAE team. In this case with Capxon, leader in the manufacture of capacitors, with which it has been collaborating for more than 13 years.

Carrying out the project with this supplier has been very easy and rewarding, as our FAE comments: "Working with Capxon FAEs has been highly enriching on a technical level and personally gratifying. Communication was always fluid, with a desire to collaborate on future projects".

Find out more about Capxon’s products on their website: https://www.capxongroup.com/index.aspx?lc=1